Heating Solutions

Heating Solutions by OTA Fiberglass Powered by TB Future

OTA Fiberglass specializes in high performance heating systems designed for demanding industrial applications, from material processing and curing to thermal protection and flow maintenance. Our full range of heating products is unified under a single, intelligent platform: The TB Future T30 smart temperature controller.

This controller delivers precise temperature control across all our heating systems, ensuring consistency, safety, and efficiency. Whether in a controlled lab, a manufacturing plant, or on a remote wind mill, OTA Fiberglass heating systems, powered by TB Future T30, bring smart, stable, and programmable heat exactly where it’s needed.

Heating solutions and applications

Heating Blankets for Composite and Epoxy Curing in Windmill repair

OTA Fiberglass industrial heating blankets are engineered with high temperature silicone exteriors and 7 mm glass insulation, making them ideal for surface heating during composite and epoxy curing processes. They are also utilized in the windmill power industry in curing and repairing rotor blade turbines. These blankets provide uniform temperature distribution, minimizing thermal gradients, and improve cure integrity.

When integrated with the TB Future T30 controller, users can set temperature thresholds up to 200°C, apply ramp up functions to prevent material stress, and enable automated shut off using the built in timer. This level of control makes them ideal for rotor blade repairs, prepreg curing, and composite bonding in aerospace, marine, and wind mill power generation.

Concrete Curing Blankets

For construction projects in cold environments, our concrete curing blankets ensure consistent hydration and strength development in poured concrete. The insulation prevents heat loss and protects the surface from frost damage.

Paired with the T30 controller, users can program controlled heating cycles and temperature holds to match hydration requirements. This solution reduces downtime in winter construction and supports higher quality structural concrete work.

Drum Heaters

Drum heaters from OTA Fiberglass are designed to wrap around standard barrels and provide even heating to maintain fluidity in contents like oils, waxes, adhesives, and food grade materials. These heaters are offered in both silicone band and jacket styles.

When used with the TB Future T30, the system provides accurate temperature maintenance, programmable heat cycles, and safety shut off to protect sensitive contents from overheating or degradation. This makes them perfect for chemical, food, and industrial storage environments.

IBC Heaters

Heating large volume materials in IBCs requires heat distribution and reliable control. OTA Fiberglass offers base heaters, sidewall jackets, and lid covers that are all optimized for compatibility with our smart control systems.

The TB Future T30 allows users to precisely regulate surface temperatures, manage long duration heating sessions, and adjust settings for material type and fluid viscosity. This is especially valuable in processing adhesives, coatings, and food ingredients.

Battery Heaters / Silicone Heating Blankets

Cold weather impacts battery efficiency and lifespan. OTA Fiberglass silicone heating blankets protect lithium ion and lead acid batteries in off grid power stations, EV systems, and telecom infrastructure.

OTA Fiberglass Heating Blankets are also used in curing Fiberglass pipes during lamination. Learn more about OTA Fiberglass Heating Blankets

The integration of TB Future T30 provides continuous monitoring, ramp up warming, and programmable hold temperatures, essential for preventing voltage drops and maintaining battery readiness in extreme conditions.

Cable and Pipe Heating

Our flexible silicone heaters for high voltage cable heating and pipe softening applications deliver targeted warmth that’s both safe and effective. These systems are crucial during cable installation or repair, and in water or gas line maintenance.

The TB Future T30 enables slow and safe warm up for large diameter or sensitive systems. It supports gradual heating curves and temperature holding, reducing the risk of insulation damage or thermal shock.

Gas Cylinder Heaters

Gas cylinders often lose pressure in cold climates, resulting in poor performance or waste. OTA Fiberglass gas cylinder heaters wrap around tanks, maintaining internal temperatures and ensuring consistent gas flow.

When controlled by the TB Future T30, gas heating becomes safer and more efficient, with precise temperature limits and automatic shutdown once optimal pressure is reached. Applications include welding systems, beverage distribution, and cryogenic gases.

Immersion Heaters

For direct heating of water, oil, and chemicals, OTA Fiberglass immersion heaters offer high efficiency and rugged construction. These are available in screw-plug, flanged, and over-the-side configurations to fit a variety of industrial tanks and containers.

Paired with the TB Future T30, these heaters provide reliable temperature holding with built-in safety features like overheat protection and internal fusing. Common uses include lab processing, tank heating, and inline heating systems.

Cartridge Heaters

For compact internal heating within molds, hot runners, or dies, OTA Fiberglass cartridge heaters offer high-watt density and robust construction. These heaters deliver fast, localized heating in packaging machines, plastics, and automation systems.

With TB Future T30 control, these heaters reach and maintain exact setpoints, minimizing energy consumption and optimizing process precision.

Ceramic Heating Elements

OTA Fiberglass ceramic heaters are built for high-temperature tasks like sealing, welding, or shrink packaging. These elements heat up quickly and distribute radiant energy efficiently in space-constrained environments.

The smart controller adds the benefit of stabilized output and automated cycles, helping extend the life of the ceramic elements while maintaining process quality.

Heat Roll Mats

Heat roll mats are used to warm up floors, temporary workstations, and large surfaces during construction or cold weather operations. OTA Fiberglass mats are flexible, waterproof, and easy to roll out.

Using the TB Future T30, operators can program heat duration, set temperature thresholds, and automate operations to avoid unnecessary energy usage. These mats are ideal for remote job sites, logistics hubs, and cold-weather curing.

Smart Control at the Center: TB Future T30

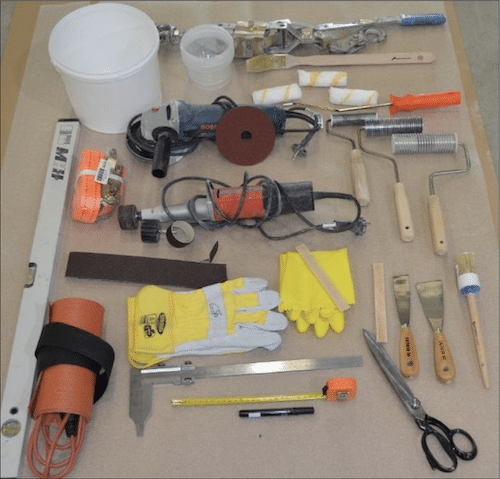

At the heart of all these heating solutions is the TB Future T30, a smart temperature controller capable of managing loads up to 7000W at 230V. Designed for industrial reliability, the T30 features:

- Digital display for real-time temperature and setpoint monitoring

- NTC-3950 sensor compatibility for accurate thermal feedback

- Ramp-up function to prevent overheating sensitive materials

- Sound Alarm When Exceeding Recommended Temperature

- IP54 rating for use in industrial and field environments

- Lightweight and easy to mount via Velcro or brackets

The T30 transforms OTA Fiberglass heaters into intelligent systems reducing manual oversight, improving consistency, and supporting process automation.

Levels of Temperature Control

Multiple TB Future T30 controllers are connectable to a single Heating Element/Product, with one, two or three sensors possible per controller or a combination of the two solutions for full control in custom applications. For instance below TB Future T30 is a 2 Sensor 2 Screens version that is useful in various industrial applications. Find out why you may need the T30 2 sensor smart temperature controller here.

Explore More

Whether you’re managing thermal curing, material preheating, or process heating, OTA Fiberglass provides complete heating systems designed to work together, powered by intelligent control. The TB Future T30 enables unmatched temperature accuracy and ease of use across all our heater types, from flexible blankets to cartridge and immersion units.

Visit us online to explore our product line: https://otaest.com

See our systems in action on YouTube: OTA Fiberglass YouTube Channel

Contact Us

Chat Now →

OR Email: [email protected] / [email protected]

Other ways to contact us: Quick inquiry form

OTA Fiberglass Headquarters: International Market, King Abdulaziz St, Al Anud, Dammam 32427, Saudi Arabia

Call/Text: +966 56 469 7032 (KSA) / 058 032 2208 / 059 275 1918

| Reengineer Value |