GRE Pipe Lamination Butt-Joint Tutorial

This quick guide demonstrates how to perform butt joints using OTA Fiberglass Pipe Tools. the whole butt and wrap joint fiberglass process including the Lamination for rtr/grp/gre/grup and other frp pipes on Site. no matter the type of pipe/its origin, this easy-to-follow tutorial as well as the video below will help explain all about lamination butt joints.

VS Other Types Of Joints: Adhesive Joints Featuring

Fibreglass Pipe Shaver:

By Using OTA Fiberglass Pipe Shaver To cut tapers on fiberglass pipes

Butt and Wrap Lamination Joint

The butt-and-wrap joint typically consists of two plain pipe ends which have been prepared for joining by sanding, Preparing and laminating the outside surface in the joint area.

Butt and Wrap Joint Assembly instructions

What is The Laminate Made of?

Resin Mixture/System

Fiberglass Reinforcement Materials

This depends on the pipe manufacturer. Chopped Strand Mat and Woving Roving anywhere from 270gm/m2 to 700gm/m2

Other materials like boat tape, surface veil, etc may be added as per Pipe manufacturer’s recommendation. please refer to the pipe manufacturer’s catalog Or Contact us through Chat – Online Now

Steps

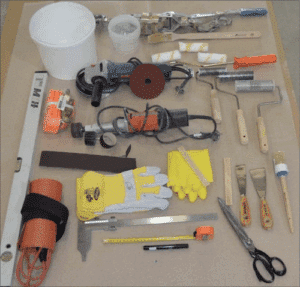

Equipment Check

- Hacksaw

- Abrasive Cutting Disc

- Pipe

- Supports

- WhiteMarker

- Wrap-Around

- Flapper-Wheel

- Drilling Machine

- Balance(WeighingScale)

- Fiberglass Laminating Rollers

- Heating Blankets

- Resin Mixer

- Paint Brush

- Rubber Scraper Plate

Pipe Cutting

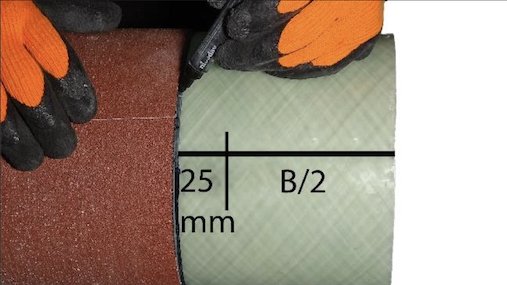

I. Preparation of Lamination Area.

II. Sand the pipe

Sand or grind the crosssection of the pipes (the cut ends) as well.

Apply Adhesive Layer

III. Connect The Pipe Ends With Adhesive

Cure The Adhesive

IV. Apply A Heating Blanket

Lamination

V. Apply laminate Layers to the joint

After Sanding the surface in previous step, The pipe Ends should be clean and dry. If not, then dry Again with a heating blanket for at least 15 minutes. Make sure each applied laminate layer of Chopped strand mat and woven roving is thoroughly impregnated with the resin mixture. See video below details on how we mix laminate layers with resin – how to structure, sequence and overlap laminates, quantities of fiberglass reinforcement materials and resin mixture involved in lamination.

During the wrapping process, press The resin out of the layer Using aluminum rollers. This helps prevent uneven surfaces from forming in the lamination layer while also rolling out air bubbles. watch the video below for the full lamination process.

Cure The Laminated layers

VI. Apply A Heating Blanket to the laminated layers

to ensure proper curing use the blanket size matching the pipes. Cure the laminate for 3-4 hours until the laminate is cold and solid. Throughout the process, monitor the temperature of the heating blanket every 15-30 minutes. OTA Fiberglass Heating Blankets Come each with an external thermostat unit – OTA Fiberglass split regulator which we designed for uniform heating in variable weather conditions.

After curing, use sandpaper to remove the rough edges of the laminate and to generally smooth out the external surface.

About OTA Fiberglass Engineering®

OTA Fiberglass Engineering® Scope/Services: Lamination Butt Wrap Joints for Frp, Gre, bonding, butt-joint, adhesive joint, chemical, lifting belt, piping, pipeline, RTRP, thermosetting resin. 6″ PDO / ARAMCO / RASGAS / ADNOC / GRE Pipes RTRP Pipes, FPI Pipes, FRP Pipes non metallic pipe Malayalam Hindi English CPI Pipes, FGS Pipes, Amipox, And More.

TOOLS, EQUIPMENT & MACHINERY:

Pipe Shaver (notably mentioned above), Heating Blanket, Barcol Tester, Laminating Rollers/Brushes, Catalyst Dispenser, Diamond Cutters, Sanding Wheels, PI Tapes, Circometer, Thickness Measuring Gauge, Demoulding Wedges.

WE offer Lamination material and pipe specialized tools – Please contact us through Chat – Online Now – For Stock Pickups and 3-5 Day Delivery -Available 24/7

Contact Us

Chat Now →

OR Email: [email protected] / [email protected]

Other ways to contact us: Quick inquiry form

OTA Fiberglass Headquarters: International Market, King Abdulaziz St, Al Anud, Dammam 32427, Saudi Arabia

Call/Text: +966 56 469 7032 (KSA) / 058 032 2208 / 059 275 1918

| Reengineer Value |