Tips & Guides

-

How To Choose Cordless Impact Wrench

In professional workshops and industrial sites, efficiency depends on using the right tools. Impact wrenches are a must-have when it comes to

Read More -

How To Choose The Right Angle Grinder?

When it comes to cutting, grinding, polishing, or shaping materials, the angle grinder is one of the most versatile power tools in any

Read More -

Wind Turbine Curing Blankets

OTA Fiberglass’s wind turbine blade curing blankets powered by TB Future T30 smart controller for precise composite curing.

Read More -

Industrial Drum Heating Blankets

Industrial drum heating blankets. Achieve safe, even heating with silicone insulated jackets powered by the TB Future T30 smart controller.

Read More -

Heating Solutions

Industrial heating for demanding industrial applications, from material processing and curing to thermal protection and flow maintenance

Read More -

How GRP Pipe Lamination Impacts Long-Term System Performance

Discover how GRP pipe lamination enhances system performance, durability, and chemical resistance. Learn about key raw materials and tools from OTA Fiberglass.

Read More -

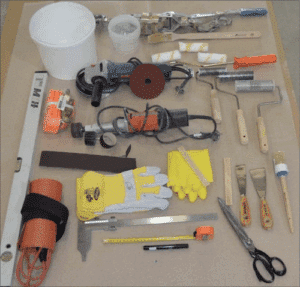

GRE and FRP Lamination Safety Tips for Field Installers

Discover essential GRE and FRP lamination safety tips for field installers. Learn best practices in PPE, resin handling, surface prep, and fiberglass pipe installation for reliable, hazard-free joints.

Read More -

How to Use a Pipe Shaver Tool Effectively for GRE/FRP Pipe

In this blog, we explore how to use a pipe shaver tool effectively for GRE/FRP pipes and how OTA Fiberglass Pipe Shaving Machine is setting new standards for precision and performance.

Read More -

Heating Blankets for GRE & RTR Pipe Lamination: Field-Ready Curing Solutions

In the world of GRE (Glass Reinforced Epoxy) and RTR (Reinforced Thermosetting Resin) piping systems, quality and durability depend heavily on the precision of field operations, especially during lamination and joint curing. Improper curing can lead to compromised bond strength, leaks, or even premature system failure.

Read More -

How to Install GRE Lamination Kits: Tools, Techniques, and Tips

Discover how GRE lamination kits ensure durable, corrosion-resistant pipe joints in GRE and GRP systems. Learn about techniques, tools, and best practices for reliable installation.

Read More -

How to Laminate Fiberglass Pipes with Adhesive Joints | Guide

Learn the complete process of laminating GRE and GRP fiberglass pipes using adhesive joints. From surface prep to curing, this guide covers every step for a durable, high-performance bond.

Read More -

Pipeline Corrosion Protection and Corrosion Under Insulation Solution

Pipeline corrosion protection is crucial because corrosion can make water unfit for drinking. It can also expose the environment to harmful materials. Equipment damage and product leakage, particularly in the oil and gas and chemical industry, pose significant environmental threats- increasing operating costs and ultimately destroying your investment.

Read More -

GRE Pipe Lamination Butt-Joint Tutorial

This quick guide demonstrates how to perform butt joints using OTA Fiberglass Pipe Tools. the whole butt and wrap joint fiberglass process including the Lamination for rtr/grp/gre/grup and other frp pipes on Site.

Read More -

Difference Between GRE and GRP Pipes

The main difference between GRE and GRP is the matrix material resin used for bonding the glass fiber. GRP pipes use Isophthalic Resin while GRE pipes use epoxy resin. Read on or watch the video to learn how this key difference affects pipe properties and application in GRE, GRP, and other types of FRP Pipes.

Read More

Contact Us

Chat Now →

OR Email: [email protected] / [email protected]

Other ways to contact us: Quick inquiry form

OTA Fiberglass Headquarters: International Market, King Abdulaziz St, Al Anud, Dammam 32427, Saudi Arabia

Call/Text: +966 56 469 7032 (KSA) / 058 032 2208 / 059 275 1918

| Reengineer Value |