How to Use a Pipe Shaver Tool Effectively for GRE/FRP Pipe

In the world of industrial piping systems, Glass Reinforced Epoxy (GRE) and Fiber Reinforced Plastic (FRP) pipes are widely used for their corrosion resistance, strength, and lightweight properties. These pipes are commonly seen in oil and gas, offshore, chemical, and water treatment applications. However, the fiberglass pipe installation and maintenance of these pipes comes with specific challenges, particularly when it comes to preparing the pipe ends for proper bonding or coupling.

One essential solution is using a pipe shaver tool for GRE/FRP pipe, which ensures clean and consistent pipe end preparation. This tool, also known as a GRE pipe shaver, plays a crucial role in improving joint integrity, reducing installation time, and preventing long-term system failures.

In this blog, we explore how to use a pipe shaver tool effectively for GRE/FRP pipes and how OTA Fiberglass Pipe Shaving Machine is setting new standards for precision and performance.

Why Pipe Shaving is Critical for GRE/FRP Pipes

Before diving into the process, let’s first understand why pipe shaving is necessary for GRE and FRP piping systems.

When GRE or FRP pipes are manufactured, the external surface often includes a resin-rich layer or protective coating. This layer, while beneficial during storage and transport, can inhibit proper bonding if not removed during installation. For bonded joints or couplings to adhere effectively, the exposed area needs to be clean, even, and consistent also free from resin layers, irregularities, or surface contamination.

Pipe shaving is a critical step in preparing fiberglass pipe installation for adhesive joints. It ensures:

- Uniform removal of the resin-rich surface

- Clean exposure of the underlying glass fibers

- Consistent pipe diameter and surface texture for optimal adhesive bonding

With automatic shaving, additional advantages include:

- Improved safety and reliability through precise, controlled material removal

- Reduced dust generation, creating a cleaner and healthier work environment

- Enhanced user comfort, minimizing manual effort and operator fatigue

Automatic shaving not only boosts efficiency but also contributes to long-term performance and durability of bonded joints.

What is a Pipe Shaver Tool?

A pipe shaver (also known as a shaving machine) is a specialized device used to remove the outer resin-rich layer of GRE (Glass Reinforced Epoxy) or FRP (Fiber Reinforced Plastic) pipes. This process is essential for cutting the appropriate GRE GRP tapering on the spigot (male end) to ensure strong bond integrity with the female end of the pipe. Pipe shavers can be manually operated or motor-driven and typically use adjustable rubber O-ring arbors, which allow the tool to fit easily within a range of pipe inner diameters. These arbors hold the shaver securely in place, ensuring precise and consistent shaving.

A high-quality pipe shaver offers:

Precision cutting depth

Uniform shaving around the circumference

Time efficiency in field or Industrial environments

Safety and ergonomic design.

Step-by-Step Guide to Using a Pipe Shaver Effectively

Here’s how you can effectively use a pipe shaver tool for GRE/FRP pipe preparation:

1. Choose the Right Shaver for Your Pipe

Not all pipe shavers are created equal. You need a tool that matches the pipe diameter, wall thickness, and desired cutting depth. For example, the OTA Fiberglass Pipe Shaver supports a wide range of pipe sizes and offers precise, adjustable shaving mechanisms.

Make sure the shaver:

- Supports your pipe size (commonly from 1” up to 24” and beyond)

- Features adjustable blade depth, allowing control over the shaving length to achieve the required taper on the spigot

- Provides a secure fit during operation through an expandable rubber O-ring arbor, ensuring stability and precision while shaving.

2. Measure and Mark the Shaving Length

Before shaving, identify the required bonded joint preparation length as specified by the pipe manufacturer or project specifications. Mark this length clearly around the pipe circumference using a measuring tape and marker. This ensures that you shave the correct length without over-cutting or under-preparing.

3. Secure the Pipe

Stability is key. Make sure the pipe is clamped securely using a pipe vise or a similar tool to prevent any movement during shaving.

4. Install and Calibrate the Shaver

A smooth, accurate shave depends on correctly installing and calibrating your pipe shaver. Follow these steps:

4.1 Fit the Shaver to the Pipe

- Select the appropriate expandable rubber O‑ring arbor for your inner diameter pipe.

- Insert the arbor fully into the spigot pipe so it’s flush with the end.

- Slide the shaver tool into the pipe until the arbor engages evenly.

- Tighten the central tensioning bolt until the support roller rests firmly against the arbor, this ensures the shaver is mounted squarely and won’t vibrate

4.2 Set Cutting Depth

- Loosen the cutting tool’s clamping bolt.

- Turn the depth-adjustment screw

- Tighten the clamping bolt to lock the blade at the desired depth.

4.3 Calibrate Shaving Length and Taper

- Align the shaving length with your required taper and bond specifications. This determines how far the shaver will travel along the spigot.

- Fully retract the tool before starting, turn the feed assembly outward, so the cutting tool is clear of the pipe, preventing accidental cuts.

4.4 Engage Power Drive and Shave

- Attach the power drive (manual or motor-driven model, such as Ridgid 700) to the adapter on the shaver shaft and engage the drive mechanism

- Rotate the tool clockwise; the automatic feed will advance the cutting tool steadily.

- Monitor the process; once the desired shaving length or final spigot diameter is reached, the feed mechanism disengages (on some models)

4.5 Finish and Remove

- Retract the cutting tool fully to clear the pipe.

- Release the central tension bolt.

- Withdraw the shaver straight out to avoid damaging the freshly shaved spigot edge

5. Clean the Surface

Before applying adhesive or installing a coupling:

- Wipe the shaved area with a lint-free cloth

- Use solvent or alcohol-based cleaner to remove dust or debris

- Avoid touching the shaved surface with bare hands to prevent contamination

6. Perform the Shaving Operation

Once set up:

- Start the machine using the OToAworks 230V power supply (or manually, depending on the model)

- Apply consistent feed pressure as the shaver moves along the marked section

- Maintain steady speed to avoid chatter marks.

The OTA Fiberglass Pipe Shaving Machine uses a rotary cutting mechanism, making it the ideal pipe tapering tool for GRE/FRP pipe shaving.

Common Mistakes to Avoid

Even with the right FRP pipe tools, improper techniques can compromise pipe performance. Watch out for:

- Excessive material removal – Weakens the pipe and affects diameter tolerances

- Uneven shaving – Can lead to adhesive gaps or joint failure

- Using dull blades – Causes tearing of fibers rather than clean shaving

- Improper calibration – Results in inconsistent joint preparation

Why Choose OTA Fiberglass Pipe Shaving Machine?

The machine stands out for its:

- Precision-engineered for GRP/GRE/FRP/RTR pipe shaving and tapering

- Durable design with a full lifetime warranty covering the shaver, arbors, and PowerDrive

- Field-proven performance supported by operational and setup videos

- Designed for versatile applications in both on-site and factory settings, with portability that allows for easy transport and setup across different work environments.

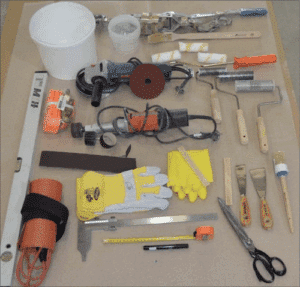

- Complete kit includes all necessary parts and FRP pipe tools

- Global support via 24/7 contact and listed international distributors

Watch our YouTube video to learn how to use the pipe shaver effectively for your next project.

Whether you’re working on a GRE piping system for desalination, or installing FRP lines in a refinery, OTA provides the tools and support to ensure consistent, high-quality results.

Conclusion

Fiberglass/RTR/GRP shaving is more than just a preparatory step; it’s a critical component of GRE/FRP piping system integrity. By using a reliable, precision pipe shaver like OTA Fiberglass shaving machine and following best practices, you can ensure superior bonding performance, reduced maintenance issues, and extended system life.

If you’re in the market for a high-performance, durable, and field-tested pipe shaving tool, check out OTA Pipe Shaving Machine today.

Contact Us

Chat Now →

OR Email: [email protected] / [email protected]

Other ways to contact us: Quick inquiry form

OTA Fiberglass Headquarters: International Market, King Abdulaziz St, Al Anud, Dammam 32427, Saudi Arabia

Call/Text: +966 56 469 7032 (KSA) / 058 032 2208 / 059 275 1918

| Reengineer Value |